Manufacturing requires a lot of heat.

According to the World Business Council for Sustainable Development, 15% of global greenhouse gas emissions result from industrial heat. At least a third of that heat is generated in the form of steam.

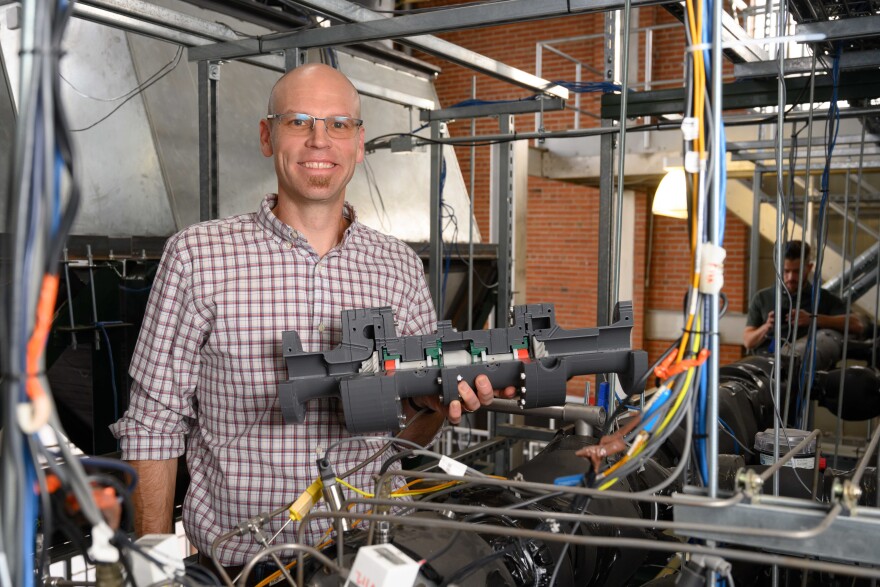

But Todd Bandhauer, a professor at Colorado State University, has developed a supercharged heat pump that can replace the gas-powered boilers used to make steam.

The new technology uses electricity, removing the natural gas emissions involved with one of industry’s most common processes.

Bandhauer’s invention landed him on the TIME100 list as one of the most influential climate leaders of 2025.

Atmos Zero, the company he co-founded, installed a pilot version of the heat pump at New Belgium Brewing this year.

Bandhauer told Aspen Public Radio’s Michael Fanelli that the product fills an untapped need that all sorts of industries are excited to get their hands on. With a factory in Loveland up and running, the company is ready to start shipping next year.

The conversation below has been edited for clarity and length.

Michael Fanelli: Tell me a little bit more about the product itself. There's one main product that you develop, right, this industrial heat pump?

Todd Bandauer: Yeah, it's a steam-generating heat pump. And it's a super powerful heat pump, basically going from really, really cold, below 0 degrees F, all the way up to 400 degrees F — steam — that we're delivering. So it's a huge temperature lift — a lot different than what you would see, for example, at your home. So it's different technology and requires very, very, very efficient compressors and lots of heat integration. And this is basically my area of expertise that I've been developing for the last couple decades.

What's interesting about steam is it's the main ingredient in industry. Steam is used to make beer, but it's used for all sorts of products, even sunscreen, milk, paper products — you name it. And by electrifying it, we can have a huge impact. So just to give you a sense of the impact, about 8% of all energy consumed in the world is used to make steam for industry.

MF: Wow, that's fascinating. I did not realize that.

TB: It's kind of shocking how much steam is used. I mean steam is literally the ingredient that drove the Industrial Revolution, and it really has not been — the steam boiler has not been reinvented in 160 years. And so that is basically what we are doing, is we're taking homegrown innovation in the U.S. — American made innovation — and using it to reimagine the boiler room and electrify it.

MF: So when I first saw this, I was like, “Well, we've had electric heat pumps, right? This isn't new technology.” But it sounds like the main difference between the electric heat pumps we might have in a home or building and this is that these, like you were saying, require more — a bigger heat transfer, because you're making steam, not just warm air.

TB: Yeah exactly, you're making steam. You're not making warm air. So there's a huge temperature rise. Here's another really key innovation, though, is that we are making a product, not a project. Industry wants our product because we can literally land it, connect electricity, connect feed water and connect steam, turn it on and don't even interrupt their process at all. So that’s one of the key reasons why we went to an air-source heat pump. So basically, we don’t have to do any complex integration.

MF: What makes it so efficient?

TB: So the way I like to describe it is the compressors are the engine of the heat pump. If you want a very efficient car, you have to have an efficient engine. So we essentially have the most efficient compressor technologies incorporated inside of our heat pump. The other thing that we do is we take great care in capturing all the heat within the cycle. So the incumbent option to electrify steam is just basically a resistance boiler. So you get one unit of heat out for one unit of electricity in. We, through heat pumping, cut that in half, and that is really what makes it more efficient.

MF: I’m wondering if you can just reflect a little bit on the TIME100, why do you think this was recognized to be on that list with all these forward thinking leaders?

TB: It's kind of like an underappreciated problem or challenge, right? Steam is so ubiquitous, and it's not something we really talk about. We talk about cars, talk about airplanes, don't necessarily talk about steam for industry. And so I think that is one of the things that interested them. The other thing, which I think is very important and has been a driving force for my entire career, is I've always wanted to have a real-world, measurable impact. And that's what we're doing here. This is not some fake solution on a piece of paper. You can go to New Belgium. You can touch it. You can hear it. You can’t smell it, because it’s zero emissions. And it literally started in a lab, became a prototype, and is now a pilot in the field, ready to scale to address this major challenge.

MF: Well, congrats again, and thanks for taking the time to chat today. I really appreciate it.

TB: K, see ya Michael.